Tabs Extra Length

Production > Plate Cutting Data > Knuckles > Tabs Extra Length

Tabs are pieces of additional material left on a knuckled plate when the plate is cut. The purpose of tabs is to prevent damage to plate edges and ensure the knuckled plate maintains its form when it is bent in production, as well as to facilitate the welding of plates together. Tabs ensure that there is enough material along the entire knuckle line to allow bending without influencing areas of the plate that should remain flat.

Tabs can be marked on the coded plate. Tabs may appear close to the ends of the knuckle line and inside holes or notches near the knuckle line. The system will add a maximum of 16 tabs on one plate.

Note: A model file is required for the marking symbol. There is no model file for the tab symbol in the default norms. Users should create their own model file and name it tab.mod, and save it in the %ncgmodellen% folder of the project (mod2d by default).

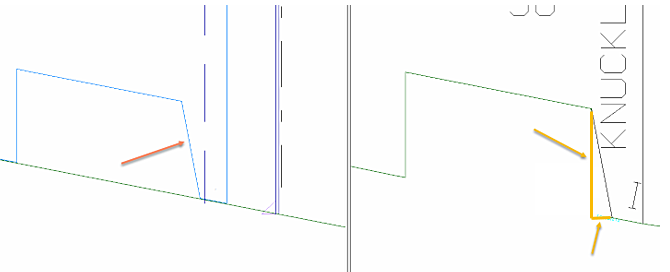

The system places the tab symbol halfway the original contour, on the side to be cut off after bending.

Tab symbol on a hole

Tabs Extra Length settings

The following settings control the adding of tabs in the coded plate.

Tab Distance

The distance from the knuckle line to a plate contour or hole that the system considers when evaluating if a tab should be added.

The default value 0.0 means that tabs are not added to the coded plate.

Minimum Part Thickness

The minimum thickness a plate must have to be considered for tabs.

The default value 0.0 means that all plates are considered for tabs.

Minimum Angle

The minimum angle that a plate segment must have to the knuckle line for the plate segment to get a tab. This setting can be used to prevent almost parallel segments (segments with a very small angle between them) near the knuckle to be enclosed by a tab.

Plate segments whose angle with the knuckle line falls between the minimum and maximum values will get a tab.

Maximum Angle

The maximum angle that a plate segment can have to the knuckle line for the plate segment to get a tab.

Plate segments whose angle with the knuckle line falls between the minimum and maximum values will get a tab.

Maximum Hole Area For Marking

In case the system adds a tab in a place on the plate where the tab only partially covers a hole, one part of the hole is marked for cutting later (the part with the tab) and the remaining part is cut. The remaining part may be so small that it would not make sense to cut it, but instead mark the entire hole to be cut later (after bending).

With this setting you can define the minimum allowed size for the remaining part to be cut. The size is defined in square mm.

-

When the area of the remaining part is larger than the value set here, it will be cut, and only the area covered by the tab will be marked.

-

When the area of the remaining part is smaller than the value set here, the entire hole will be marked, and no part will be cut immediately.

The default value 0.0 means that all holes that any remaining part of the hole, no matter how small, will be cut.

The purpose of this setting is to prevent small holes from being left on the plate.