Elongation Report for Shell Plates

This chapter contains all information you need to know about elongation reports in order to create shell plates that can be successfully bent at the production site.

It’s important to be aware of the fact that the bending process does not only change the shape of the shell plate. It also affects the size of the plate depending on the bending method and the material. Elongation is used to compensate for the changes in the size of the shell plate due to the bending process.

The elongation report is an .XLS file that contains all necessary information for the production team about the elongation required to successfully produce the shell plate.

Note: The standard norm in our examples does not comply with the very specific values that are appropriate for your production.

The system manager should customize these reports to make sure that the plates can be properly bent by production.

The system automatically creates an elongation report when coding the shell plate. To create a report for each shell plate the system uses a template file in the norms/cvar folder of the project. The name of the template file is elongationreport.xls and it should be customized by the system manager.

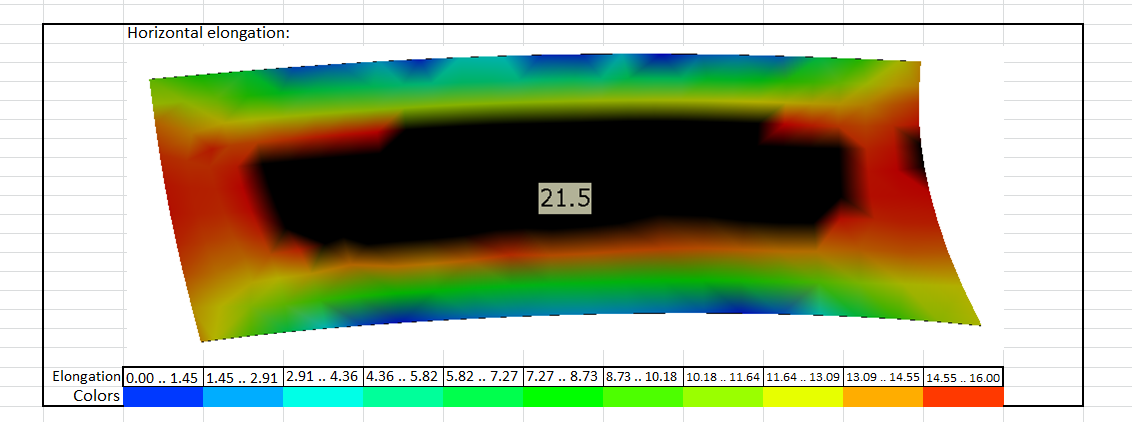

The example image below shows how the layout of the elongation report looks like:

The elongation report contains the following parts:

- General shell plate information

- A color scale and the respective elongation values that will help you to interpret the color map of the shell plate

- A color map of the horizontal elongation

- A color map of the vertical elongation

- A 3D image of the shell plate and - if included - of the templates that belong to the shell plate

In the elongation report values are colored based on thickness and material type. The colors used in the color maps are determined by user defined rules.

The elongation report allows the user to control results after they coded a shell plate. The color map indicates if parts of the shell plate have values that would be critical in the production phase.

In the example below you can see a spherical shaped plate with a thickness of 24mm.

The colors in this case are defined by inverse rainbow colors that range from blue (lowest values) to red (highest values). All values larger than the acceptable range are marked with black color. In this specific example production indicated that they can handle plates with a maximum elongation of 16mm per meter in length direction. The colors show clearly that this plate oversteps the indicated maximum limit by having a maximum of 21.5mm per meter elongation in the middle section.

When the elongation has exceeded the maximum values, the engineer must double-check and adjust the boundaries and the shape of the shell plate.