Q line

The Q line is a line to store end shape, hole, cutout and bevel information in the logistical database. This information can be retrieved from the database if the logistical database fields are present. This information will be added automatically if changes are made to the construction. Below a list is made of these special logistical fields:

GeneralWeldlength, Second_r1, Second_type, First_r1, First_type, Second_r2, Second_r3, Second_r4, First_r2, First_r3, First_r4, First_r6, First_r5, First_r7, First_r8, Second_r5, Second_r6, Second_r7, Second_r8, Prof_cutouts, First_bevel, Second_bevel, Third_bevel, Fourth_bevel, Third_r1, Third_r2, Fourth_r1, Fourth_r2, Prof_holes

The syntax is the same as the Robot and Bevel lines please see these chapters for more information. Below some examples how to use the Q lines:

Q** TY VD R1BH1 _1 VC _6 0 _2 0 _3 0 _4 0 _5 0 _7 0 _8 H1 WL -10 WL

QB0** TY 0

QB1** TY VP B1 H1

QB2** TY VA B1 H1

QB3** TY X B1 H1

Please take care that all not used logistical field will be set to empty (zero) values. This to avoid values from the previous end-type or situation.

Next to this Q line the aracrobot_q.ind file have to be present in your norms as well. In this file the system manager can specify some special structure. See example below:

ROBOTFILENAME "NUL"

A

B$FACE_PL_BEND_ANGLE_SIGN!BRS$FACE_PL_BEND_RADIUS!$FACE_PL_BEND5_LENGTH<->$FACE_PL_BEND6_LENGTH

B$FACE_PL_BEND_ANGLE_SIGN$FACE_PL_BEND_ANGLE!$FACE_PL_BEND3_LENGTH

LOOP

I,$R1,$TYPELENGTE,$R2,$R3,$R4,$R5,$R6,$R7,$R8

NEXT

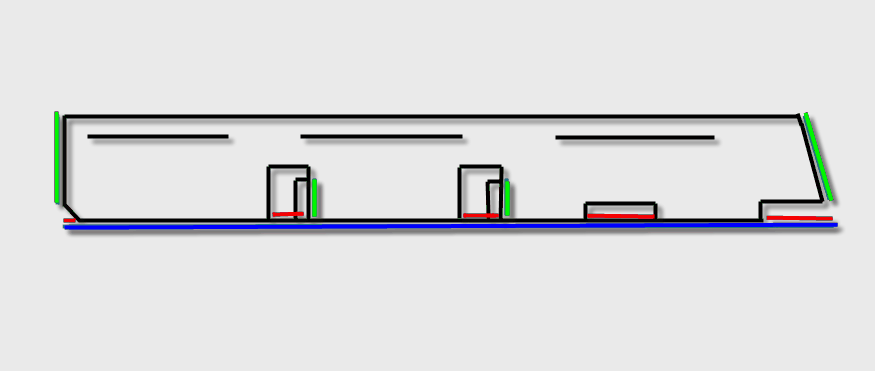

In the Q line a correction to the generalweldlength can be given by using the WL argument like 100 WL and/or -100 WL. The generalweldlength will be a combination of the profile length, cutout gaps, endtype length and profile connection in cutouts. see example below. The blue line is the total length of the profile. The green length will be the positive values in the Q** lines the read length will be the negative values in the Q** lines.

LET V1=10

LET V2=-1

Q** TY VD R1BH1 _1 VC _6 0 _2 0 _3 0 _4 0 _5 0 _7 0 _8 H1-V1 WL V1*V1 WL

H1-V1 is the green endtype length

V1*v1 is the red endtype length

The WL command have to be added in all type how have influent to the generalweldlength.