Single and matched welds

By default the system generates welds for all bevels. The welds can exist between two adjacent topologically connected parts, or they can be 'single' welds on parts which do not have a known weld counterpart because there is no topological connection to another part. A part with a single weld could have a weld counterpart, but the system does not recognize this adjacent part because its geometry is defined by fixed values or auxiliary lines, not topologically.

When Weld Manager is started, it tries to find weld counterparts to parts which have single welds based on the parts' geometry. To match a part having a single weld with an adjacent part, the system uses a threshold of 1.5 times the thickness of the part having the weld. If the distance to an adjacent part is within the threshold, the parts are matched, and the adjacent part is made the weld counterpart for the part having the weld.

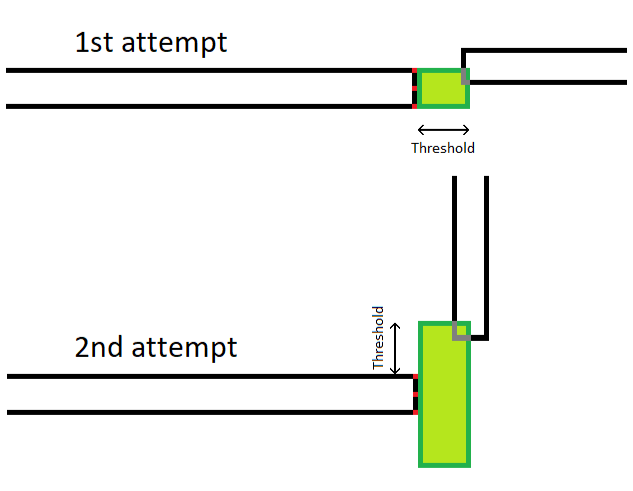

Searching for weld counterparts is done in two steps:

-

Search for an adjacent part on the same plane as the part having the single weld, within the threshold. If a match is found, searching stops.

-

If a counterpart is not found on the same plane, search for an adjacent part beyond the plane of the part having the weld, within the threshold.

Important: The system performs the search only on the parts currently shown in Hull Viewer.

Parts against the shell: The search covers welds on parts which are placed against the shell. The system will try to match these parts with (all visible) shell plates.

Weld statuses

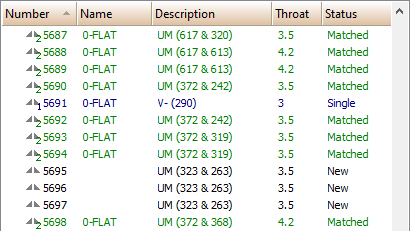

If a match for a single weld is not found, the weld remains a single weld, with status Single.

If a match is found for a single weld based on its geometry, the status of the weld becomes Matched.

Welds for which a counterpart was already known prior to the search based on their topology or bevel information have status New.

Weld side and weld factor rules

Weld side and weld factor rules cannot be evaluated for single welds because there is no information available about the adjacent part. A single weld is placed at the default weld side which is defined in the last line of the weld side rule file weldside0001.cfg.

After matching a part which had a single weld with an adjacent part, the system applies the weld side and weld factor rules to the weld between them. Therefore the weld side might change from what was defined to be the default weld side for the single weld.

Parts against the shell: Weld side rules are not applied. The default weld side is used.

Presentation in the weld list

After the search for matching parts, welds for which a counterpart was not found are shown in blue, with a blue 1 overlay on the icon, with status Single. Welds for which a counterpart was geometrically found are shown in green, with a green 2 overlay on the icon, with status Matched. Welds for which a counterpart was already known prior to the search based on their topology or bevel information have status New, and they are shown in black. The color-coding is only used in the weld list, not in the graphical window.

Clicking OK in the Weld Manager dialog saves the newly found weld data into the weld database, including data for matched and single welds, and it is thus available for weld labels, for example. Data for single welds will also be included in exported weld reports. The information in the reports for the welded part (counterpart) will be empty or 0.

Excluding single welds

It is possible to have Weld Manager show only those welds which have known counterparts based on topology. This can be done by adding the processsinglewelds keyword to the Weld Manager configuration file weldmgr.cfg and setting the keyword's value to no. This file is located in the cvar\weld folder of the norms. It is not possible to change this in the System Management application.

The processsinglewelds setting has no effect on parts which have welds against the shell.