NAPA Steel interface

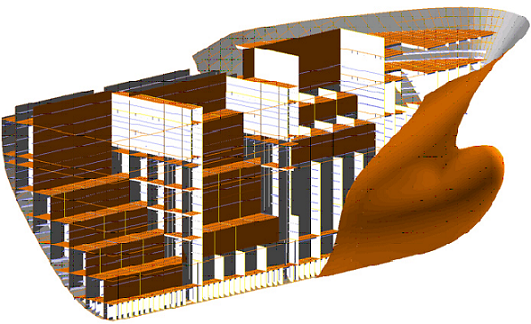

NAPA Steel designates functions for defining constructional properties of decks, bulkheads, shell plating and other ship structures, providing a 3D modeling method that is fast enough for the project stage, during which changes are frequent, while still handling enough information to serve designing needs.

A typical NAPA Steel model

A structure model used for production purposes must contain all sorts of detail information related to practical aspects of manufacturing; also, the information used in the production process needs to be more accurate. The NAPA Steel model does not take care of these details because such information is irrelevant during the initial and basic design stages.

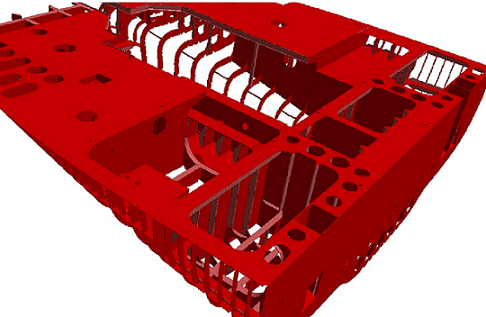

CADMATIC Hull is a 3D design and engineering system based on a 3D product model and integrates Computer Aided Design (CAD) Engineering (CAE) and Manufacturing (CAM) for the ship's hull, piping, machinery, and outfitting.

A typical detailed CADMATIC Hull model

During the (detailed) engineering stage of a ship, CADMATIC Hull's 3D product model is automatically built by the system. From this 3D model necessary production data such as NC cutting data, bending information, part lists, weights and cog lists, etc., pipe isometrics and digital data for robotized production methods can be generated directly.

The NAPA Steel to CADMATIC Hull interface makes it possible to transfer the complete NAPA Steel model to the CADMATIC Hull 3D product model. Once the model is transferred it can be used as if it was created in CADMATIC Hull. The topology in the NAPA Steel model is maintained in CADMATIC Hull.

This document gives an overview about the transfer of the model and the topology, program requirements, how the interface works and how to use it. Knowledge about NAPA Steel and CADMATIC Hull is assumed.