Insulation in pipe routing

Insulations are specified to each pipeline. Maximum three insulation specifications can be assigned to one pipeline. Insulation material and needed additional materials are defined in specification.

When you start to route pipes, you select the required insulation spec

-

If InsulationRequired is set No and some insulation spec has been assigned to pipeline, the default value when starting to route pipe is ‘No Insulation’. You select the required insulation spec.

-

If InsulationRequired is set Yes, you can define 1-3 insulation specs and assign one of them to a pipeline. You can change the insulation spec with command Piping > Check/Change > Set of Objects.

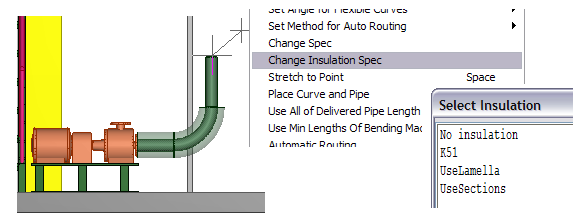

You can change insulation specification to another only in seam points of pipe. During pipe routing before finishing the pipe use the command Change Insulation Spec. If pipeline has been marked to required insulation, then you can’t choose No Insulation. Change Insulation Spec is greyed out in menu if only one insulation specification is available and insulation is set to be required.

Note: If you change insulation spec to another in the middle of straight pipe, the spec is changed from the previous seam point so that the whole straight pipe part is insulated. If you want to change insulation spec in the middle of pipe, you have to cut the pipe and spec can be changed in that point.

When you route insulated pipes, insulations are visualized during pipe routing. In order to insulations would be visualized in views after pipe routing has been finished, the setting Show insulation of objects has to be set on. Read more about visualization of insulation.

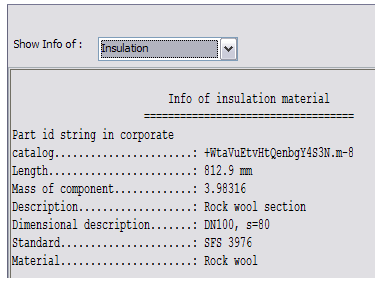

Insulation data is shown in Query Object>Show Info of Insulation. Insulation material is shown as well as additional materials needed in insulation.

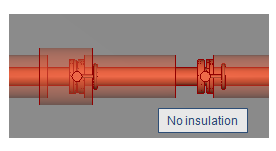

Component selection tool allows users to specify whether an object is to be insulated. This option is visible only when standard components are inserted and the context indicates that we might use insulation. In the picture below a valve is inserted both ways: insulated according to specification and not insulated.

Some notes about dimensions of insulation:

-

With steam traced pipelines section type insulation will be one size bigger than the pipe.

-

If insulation material has dimension of type diameter, it’s recognized as section type insulation. Lamella type insulation has only thickness type dimension (s=50).

-

If curves are insulated using part that has an angle dimension then this is assumed to mean max usable angle. For example if this is 15 and required angle is 85 then six pieces of insulation are needed.