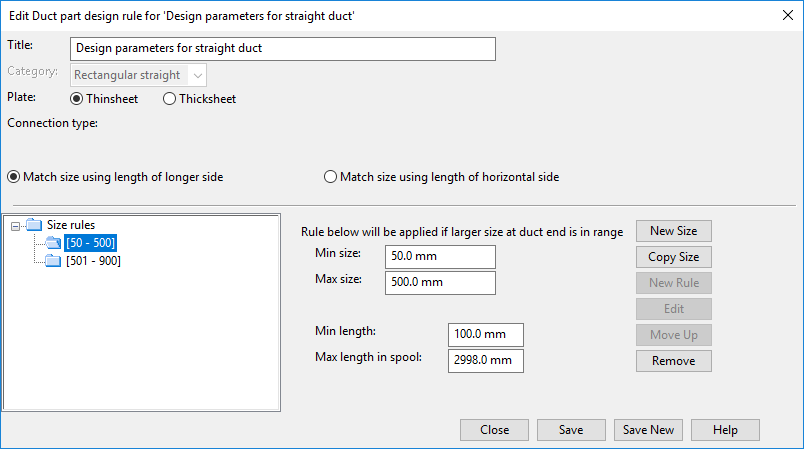

Duct part design rules for rectangular straight ducts

A duct part design rule for rectangular, straight ducts controls the minimum and maximum duct length between auto-inserted flange sets.

For each size range, you can specify the minimum length and maximum length in the spool separately. It is possible to have more than one entry in the specification for these design rules. Normally, one is enough, though, because one rule can contain different rules for different sizes.

-

Min length – This setting specifies the shortest possible length for a straight duct that uses the specification. If minimum length is not defined, 50 mm is used. This default value can be changed by editing the control value 16000 in file PMS_HOME/pm/english/message/cntvals.mmt. Absolute minimum for the default value is 10 mm.

-

Max length in spool – This setting specifies the distance that the auto-insertion tool uses between automatically inserted flange sets.

In the ducting specification, a design rule must be added under the functional code [_drst ("Rule for rectangular straight"). This functional code can be added, for example, under the component class for the duct material.

Note: For oval straight ducts, the minimum length is specified via the MinLength dimension in the dimension table.