Introduction to sister project management

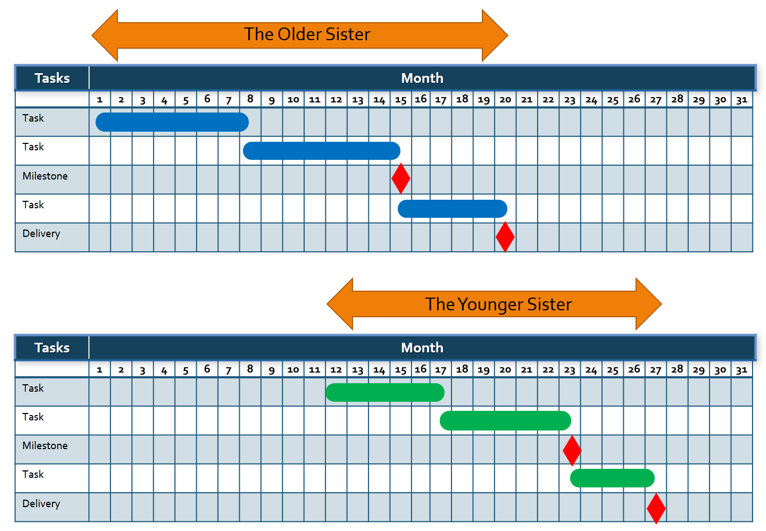

The Sister Project Management tools of CADMATIC allow handling the situation where a series of similar ships or plants are designed and constructed partly in parallel, so that there is an "older sister" that is not even near its completion when the project for a "younger sister" that largely utilizes the same design must already be started.

The younger sister shares many things from the older sister, but in practice is never an exact copy of it. There can be various reasons for the projects not being carried out in exactly the same way, such as:

- Differences in the supply chain. For example, some of the equipment might be ordered from a different vendor due to a better price or better availability.

- Differences in the material specifications. For example, some of the piping systems might require stainless steel to be used instead of plastic.

- Differences in the main design parameters. For example, the capacity, the dimensions or the general purpose might be different.

- Differences brought about by the experience gained during the older project. Usually some design changes are made to the younger project based on feedback from the construction of the older project.

In the past, managing this kind of situation has been very challenging, but by using the Sister Project Management tools in CADMATIC both the common elements and the differences can be handled in an efficient manner, throughout the life cycle of each sister project. Using these tools, the younger sister can directly utilize the work that has already been done on the older sister, and therefore the younger sister can have a considerably shorter lead time and should require fewer design hours.