Edit welds

The Edit group consists of the following functions:

Edit Path

Select Edit Path to edit the geometry of an already existing weld path.

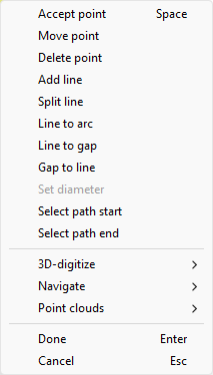

While editing in 3D, you can right-click and select the following actions:

Split Path

Select Split Path to split an existing weld path into two welds.

Delete

Select Delete to delete a selected set of welds.

Change System

Select Change System to change the system of a selected set of welds.

Attributes

-

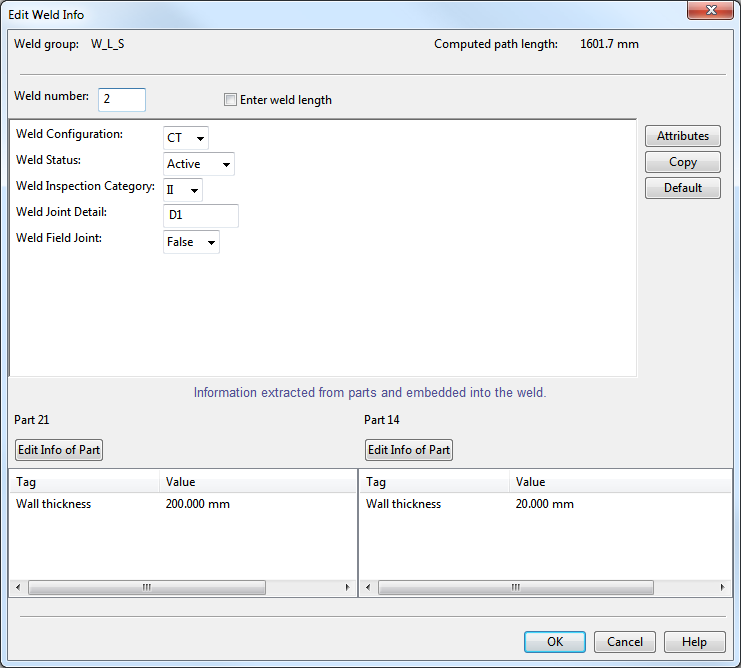

Select Attributes > Edit to edit the attributes of a weld one at a time. The Edit Weld Info dialog opens.

You can edit the values of:

-

Weld path length – Select Enter weld length to override the automatically computed value.

-

Attributes – These are assigned to the COS object type Weld.

-

Selected data of the two welded objects – Depending on the configuration, a weld published a set of information from the welded parts. You can override the computed values.

-

-

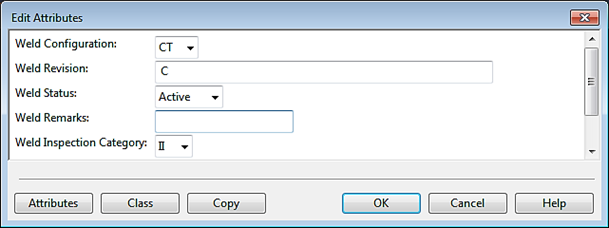

Select Attributes > Multi-Edit to edit the attributes of multiple welds. The Edit Attributes dialog opens.

Only COS attributes, assigned to the object type Weld, can be assigned.

Numbers

Weld numbers are the unique identifiers of the welds. Weld data is published in weld documents and exporting a weld list as an Excel workbook.

As long as weld data is not yet published, you might like to make your weld IDs to follow a consecutive numbering. After publishing the weld data, you cannot change the weld ids.

There are two id numbering related commands:

-

Make Consecutive – Reorganize the weld numbers of the welds whose weld number is greater than the highest weld number of the currently published welds. The unpublished welds get consecutive a weld numbers, starting from the number of the last published plus one.

-

Freeze – Set the current highest weld number to be the new highest weld number of published welds.

The highest weld number is managed per weld group and stored into the weld group data.

Note: There is no built-in connection between Make Consecutive and real document publishing, weld labeling, or Excel export. Thus, you are expected to do this before you start to work with your weld drawing (create weld labels) and before you export the weld report.