PI Revision & Export Production with XML

The Production > PI Revision Check function in the 3D-Contek application generates an XML data file of all production information of the parts in the active block, based on the Work BreakDown structure.

You can create a production information version each time you generate the XML file, allowing you to perform revision checks on the production data generated at different points of time.

Note: There are some prerequisites which must be met before you can use this function. See Production information revision check for detailed information on the prerequisites.

Import file for Nestix

It is possible to create a file for importing the production data to Nestix nesting software. There are some special prerequisites for this. See Prerequisites for creating the Nestix import file. If the prerequisites are met, the system produces a compressed ZIP archive named pi_revision_<x>.zip containing the XML file and places it into the root of the active block folder. The XML file contains all existing (already generated) production data, or reference links to production data.

The ZIP file can be directly imported to Nestix.

Exporting production data with XML

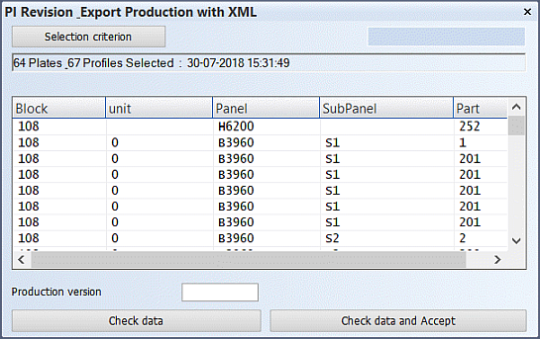

The PI Revision & Export Production with XML dialog shows the current selection of parts.

The number of plates (including shell frames) and profiles in the selections are shown in the overview field close to the top of the dialog. The list is based on the Work BreakDown structure.

Checking the data

It is recommend to use the Check data action as the first step. The dialog updates to show the status and version of the parts. The version is not changed after the check. The AttachmentType is either cuttingdata (DXF files), or ProfileXML_Cadmatic (profile XML data) , robotdata (.plf files) or partsketchdata (skecthes).

Status number 3 identifies out-of-date parts, and status number 4 identifies parts for which there is no production information. In the picture above, the status numbers have been replaced by descriptive texts defined in the logistical conversion settings (see the Tip in the PI Revision & Export Production with XML section above).

Before generating the XML output, production information should be created for parts which do not have it yet (status number 4), and out-of-date parts (status number 3) should be recalculated to update the production information.

Generating the XML output

Make sure that any missing production information is created and out-of-date parts have been recalculated.

Click Check data and Accept. The system creates the XML output. The version (Productionversion logistical field) changes.

The XML file is created in the production information folder with the name pi_revision_<x>.xml, where x stands for Productionversion. The production information folder is set in System Management > Production > General > Output Directory.The default is ./pi.

-

If the system was set up to create the ZIP file for the Nestix import, the system creates the ZIP file containing the XML file, with the correct version and status information. The system creates the ZIP file into the root of the active block folder

When the output is generated, the cuttingdata (DXF files) and robotdata (.plf files) is saved in the revision data folder. The revision data folder is set in System Management > Production > General > Revision Output Directory.