Markings for doubler plates on coded plate

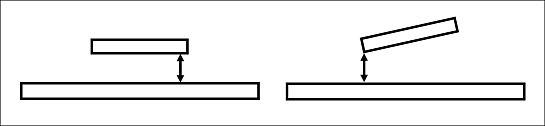

A plate or bracket which runs parallel or almost parallel on top of another plate can be considered to be a doubler plate to the plate located below it. A doubler plate is welded onto the main plate to reinforce it. The main plate can be a deck plate for example. A deviation of max 3 degrees between the plate normals is allowed for the top plate to still be considered a doubler plate.

Markings for doubler plates can be included in the coded main plate. Consider the following:

-

If the plate normals deviate at least 0.1 degrees, any arcs on the doubler plate will be converted into line segments.

-

The text added to the marking line is positioned inside the marking, along the longest segment.

-

The marking text set for the doubler plate is set in System Management > Production > Plate Cutting Data > Marking > Plate or Bracket.

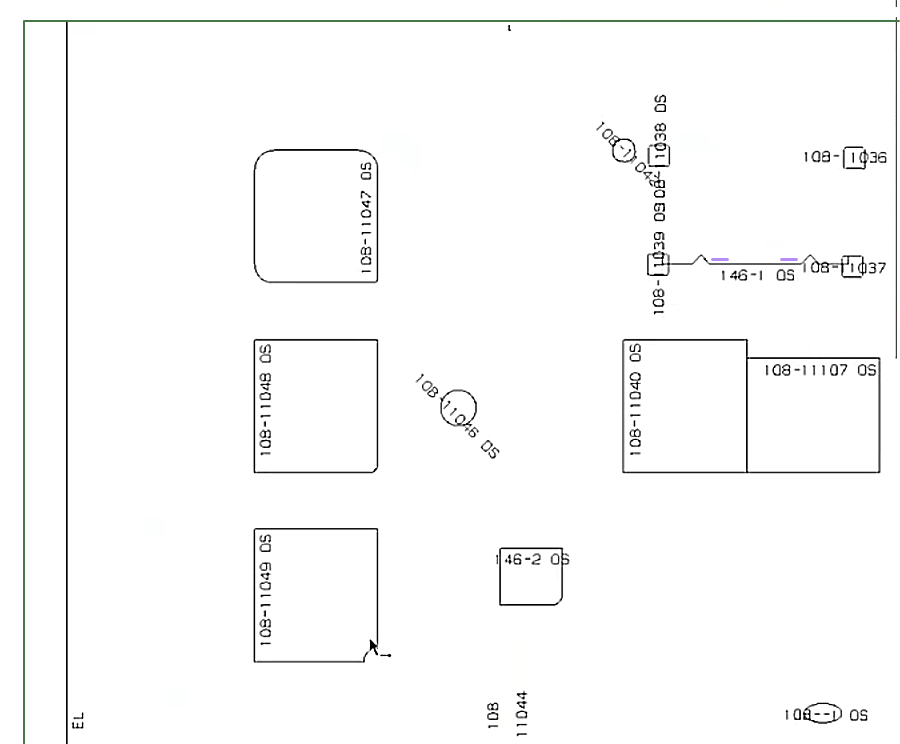

Examples of doubler plate markings on a coded plate

Settings for doubler plate markings

The following settings in Production > Plate Cutting Data > Marking > Settings control whether doubler plates are marked on the coded plate or not: Max. Distance Doubler – Main Plate and Doubler Size To Be Marked.

Max. Distance Doubler – Main Plate

The setting value defines the maximum allowed distance between the doubler plate and the main plate. When the distance between the doubler plate and the main plate is bigger than the set value, there will be no marking of the doubler plate on the main plate DXF.

If the plates are not completely parallel, the distance is the shortest distance between them.

With the default value of −1 there will be no marking regardless of the distance.

Doubler Size To Be Marked

The setting value defines the range of the allowed length and width for the doubler plate to be marked on the coded plate. Both the length and the width of the doubler plate must fall within this range or it will not be marked.

If the doubler plate is not exactly parallel to the main plate, or has an irregular shape, the size of the doubler plate is considered to be the size of the smallest rectangle around it. The contour of the doubler plate is projected onto the main plate by simply "dropping" the contour onto the plate.