Rearrange part numbers

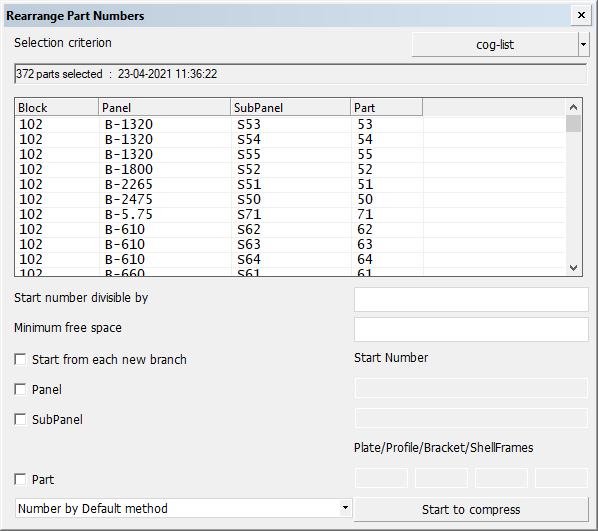

The function Logistics > Rearrange Part Numbers is useful to rearrange or compress part numbers within a given selection.

When a section or panel contains identical profiles it is possible to combine these to one part number. To check on these identical profiles please use Automatic part numbering. This function will even compress the part numbers to a nice range of numbers if the function Compress is used in this automatic part numbering function. Instead of using the Compress function in the automatic part numbering function the Rearrange Part Numbers function can be used to rearrange the part numbers or compress them manually to a nice range. To do this the next steps are necessary:

- First select with selection criteria all the part numbers that must be compressed.

- After this selection fill in the new numbers together with the method and free spaces and start the compress sequence. These actions can be repeated several times until you stop the function with the Escape button. Another panel shows the lowest and highest part number within the selection criteria.

Creating a new selection

The panel will display the number of plates or profiles that have been selected together with an overview of these parts. The displayed selection date and time indicate when this selection was made. Use the Selection criterion drop-down menu, which will open the familiar standard selection menu, in which it is possible to enter the desirable selection criteria. This will make a new selection. Once the new selection has been made, the program will automatically display the new number of items of all selected parts.

Also a Hull viewer selection can be used by selection some parts in Hull Viewer and use the Hull Viewer button in the Selection criterion.

The selection is important, because only the selected construction will be calculated. The previous selection is always the default. A new selection must be made if this selection is not up to date any more.

Start number divisible by

The given start number will be a number divisible by this number. Starting from each higher Work breakdown level. This will be used only if the start number is a valid number.

Minimum free space

If used, a minimum amount of free numbers will be available between each different higher Work breakdown level

Start from each new branch

This will take care that each different higher level will use the same starting number.

Start Number

Only Work Breakdown structure fields can be rearranged. For this reason the above panel layout will display only the available Work Breakdown structure, excluding the block number.

Only the selected Work Breakdown fields will be changed beginning with the given start number or name.

In case of the lower Work Breakdown structure, in most cases the Part number, a distinction can be made for each type of part (plate, profile, bracket, shell frame) and another distinction can be made between port (PS) and starboard (SB) see Number by Default method. All parts of a panel will be given a number simply by entering a number in the Plate input fields (the first field behind the Part Work Breakdown structure. If a value is entered in the Profiles field also, the plates and profiles will be numbered separately. In that case, the same number may occur twice and the type will determine the unique status of the part. The last method is more suitable for giving profiles a different number sequence than plates. This method can be used for Brackets and Shell frames as well.

Number by Default method

Furthermore, the user can specify whether the parts on the SB side should be given even numbers and the BB parts odd numbers or vice versa. By default, this option is set to Number by Default method, which means that all selected parts will be rearranged independent of their position.