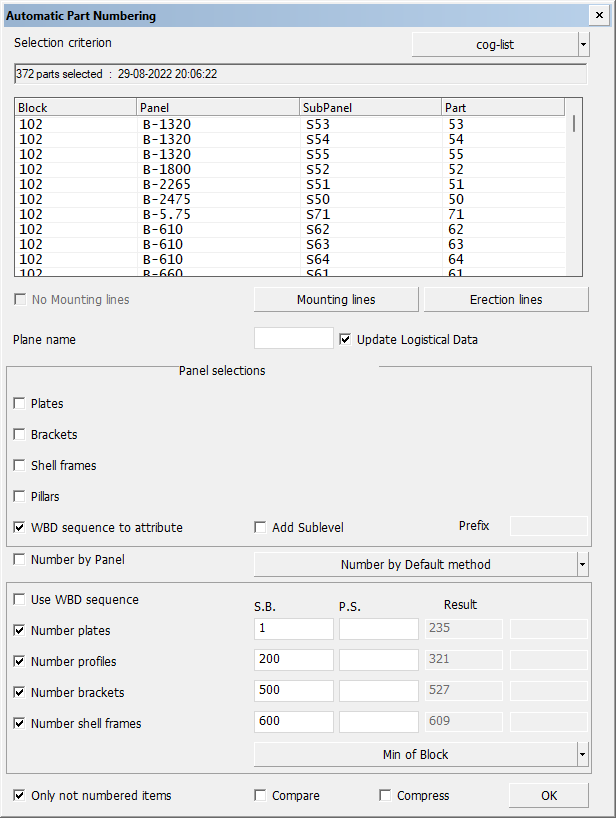

Automatic part numbering within panels

The Automatic Part Numbering function gives all parts a part number. The order of the numbering is controlled by several conditions:

- Panel name

- The chosen prpa code for each type.;

- The panel name together with the prpa appendix code controls the sequence;

- Numbering by panel or numbering by block;

- Position of the part is important within one panel;

- The chosen main and secondary direction for each type;

- The given start numbers, starboard, port side, even or odd define for each type of plate, bracket, profile or shell frame a number.;

- Compare and Compress;

- Only not numbered items.

The first step of part numbering is to give all parts a plane name and a panel name. See Panel name.

The chosen prpa code for each type.

Each construction type can get their own panel appendix code. This code is added to the panel code temporarily.

The panel name together with the prpa appendix code controls the sequence

This combined name is sorted by name and causes the first sequence. All parts with the same combined name are sorted by position in two different directions: a main direction and a sub-direction.

Numbering by panel or numbering by block

Two numbering sequences are possible: numbering by panel, or numbering by block. If numbering by panel is chosen, each panel starts with the same part number. If numbering by block is chosen, the first part number of the panel starts with the highest number of the previous panel plus 1. In this last case all part numbers are unique. In the first case all part numbers within a panel are unique. If the panel appendix code is used, the part number will be unique for each combined name.

Position of the part is important within one panel

Each part has a position. For profiles the position is at the middle of the profile length. For plates it is the position of the part number attribute. These positions are important for the two sorting sequences (see Sorting). The two sorting sequences are used within each panel.

Note: The position of the part number attribute will be moved automatically to a good position after each modification of the part, until the automatic part numbering system is used or the part number is given manually. This automatic position is based in the setting Undefined Partno. Log. Textsize.

The chosen main and secondary direction for each type

The main direction divides the panel in bands within which the part number position should be. These bands can be situated in either the height or the width direction of the panel. The secondary direction sorts the part positions within these bands, this can be done in three directions: from 'one side to the other side' or from the 'middle to each side'. With these two sequences the part positions are sorted and the order for each part is a fact.

The main and secondary sorting of plates and profiles can be set separately with the Logistics > Part Numbering > Sorting menu option of the System Management application.

The given start numbers, starboard, port side, even or odd define for each type of plate, bracket, profile or shell frame a number.

The automatic part numbering process has several options for numbering parts. A distinction can be made for each type of part (plate, profile, bracket, shell frame), and another distinction can be made between port side (PS) and starboard (SB).

Note: The work breakdown sequence in automatic part numbering will restructure the tree so that all attributes will be below the plate level.

You can select whether the parts on the SB side should be given even numbers and the PS parts odd numbers or the other way around. By default this option is set to Number by Default Method, which means that the sorting direction will determine the numbers.

All parts of a panel are given a unique number simply by entering a value for S.B. in Number plates.

If a value is entered in Number profiles, the plates and profiles will be numbered separately. In that case, the same number may occur twice and the profile type will determine the unique status of the part. This method is more suitable for giving profiles a number different sequence different than is given for plates.

The default settings for each part number can be found in Starting Numbers.

Compare

If this option is selected, the system checks the entire block for identical profiles. If identical profiles are found, they are grouped and given the same part number. If the Count Mirrored Profiles setting (See Settings) is enabled, the Compare function will treat mirrored profiles as the same. An extra line will be shown in the panel.

Note: The check does not include plate attributes, marking or bevel data. Lugs are not checked whether they are identical or not.

The profiles will use the content from the type file aracrobot.pap and check if the (profile id name)d.pap and (profile id name)m.pap are identical. If this is the case, they get the same part number.

Note: The content of the aracrobot.pap file should be complete, including flange and bevel data. For the bevel data you need to add the bevel lines into the type definition. Do not forget to insert the bevel mirror conditions as well.

Note on Lugs

If the Compare option is selected, the system gives the same part number to lugs that are identical with respect to the following properties:

-

Type number (including alternative types)

-

Netto weight

-

Material

-

Thickness

The system makes a distinction between the starboard and port side, and gives different part numbers to similar lugs on SB and PS if the user selects a numbering method other than the default method. With the default numbering method, similar lugs get the same part number regardless of the side of the center line they are located on.

Compress

If the Compress option is selected, all items within the entire block will be compressed according to the given start numbers. This function can also used alone. See also Rearrange part numbers.

Only not numbered items

This option can be used when a block is already numbered and only not numbered parts must have a number. If this is the case, enter the highest number plus one in the input fields. This is to prevent identical part numbers on not identical (plate) parts.

Note: The Compare function will always check all parts in the block while Compress will always use the selected parts. For this reason it is not always wise to use these functions together with Only not numbered items, especially if you do not want to change the older part numbers.