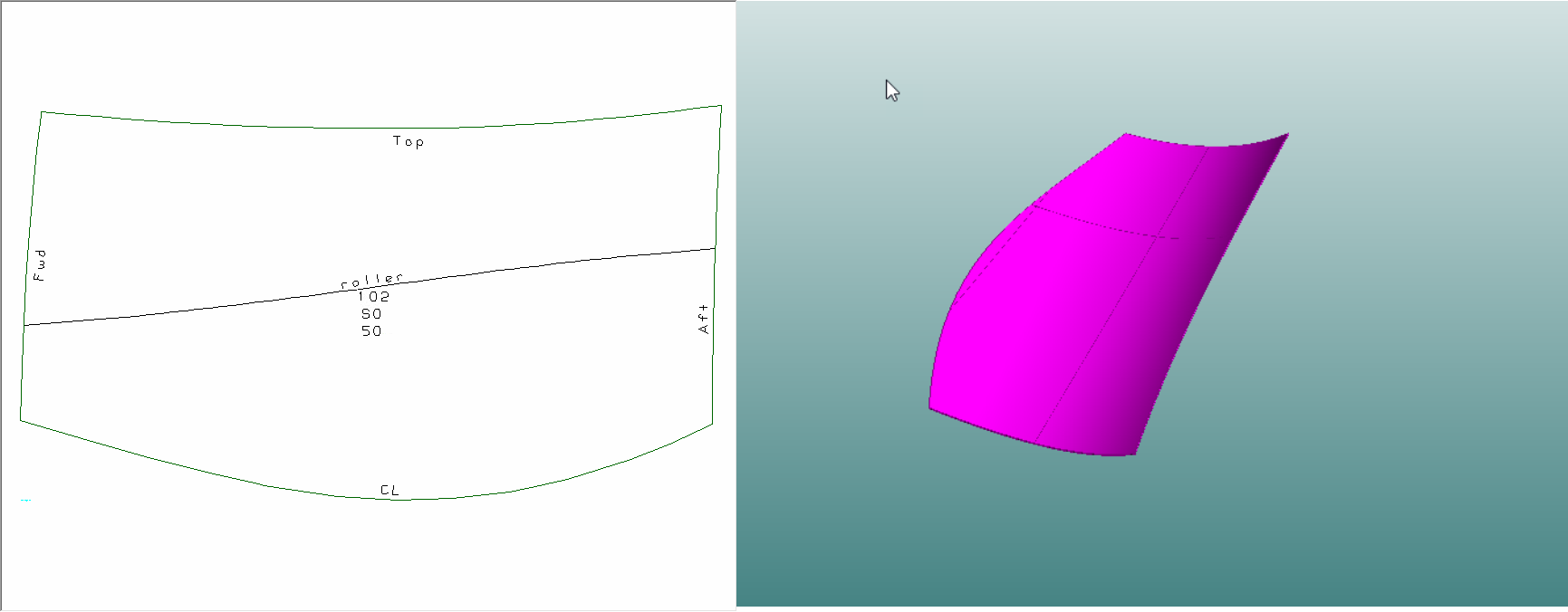

Including roller lines

To assist with the unfolding of the shell plates, a special marking line named 'roller line' can be included in the plate cutting data. This line is a useful aid in case of cold forming and line heating as well.

The roller line is only calculated for simply curved plates. It is not calculated for plates that are flat or curved in multiple directions. Flat parts of the shell plate are not selected for the calculation of the roller line. The roller line indicates the roller or bending direction. This direction is perpendicular to the line itself.

There are two methods available:

- Cold forming – The line defined is just one of many possibilities, but it is chosen because it is the one that is more closely related to the other folding process.

- Line heating – The curve resulting from using line heating calculations will be approximated by a straight line, as the line heating method cannot deal with a curved roller line. The approximation is done using the least squares method (similar to statistical linear regression).

Using the line heating method, the calculated roller line must be longer than 60% of the length of the roller line after extending its ends to the shell plate contour. It must also be longer than √2 times the value set for Roller Line Grid Distance. If it is shorter, the roller line will be omitted.

The following two settings in the System Management application can be used to influence the presentation of the roller line in the plate cutting data:

- Roller Line Text

- Roller Line Grid Distance

See Production > Plate Cutting Data > Shell Plates > Settings in the System Management application help for more information on these settings.