Bevels on plates split by seams

Plates which have soft seams splitting the plate into two or more pieces are called panels. The pieces resulting from the splitting are called plate parts. In addition to soft seams, plates can also be split by slots/splitters or holes, or a combination of these.

The panel remains a single entity in the Hull construction database, but the plate parts have their own logistical record, and can therefore have different thicknesses and material types. The thickness and material type can be changed individually for each plate part. Shrinkage compensation is applied on the complete panel.

Bevel Generator takes the properties (thickness and material) of the plate parts of panels into account when determining the bevels at seams, slots/splitters and at the ends of pillars, profiles, shell frames and face plates.

When bevels are generated with Bevel Generator, the seams between the plate parts get a bevel at both sides of the seam. The bevels are determined according to the properties of the plate parts. Bevel generator will not generate counterpart bevels for manually placed bevels at seams. The direction of the bevel model on a seam follows the plate part's contour direction. Slots/splitters get bevels the same way as seams.

Weld lines are created for each plate part contour which is delimited by a seam, slot/splitter or plate edge. The generated weld information (weld method, throat height) is based on the properties of the plate parts.

The system evaluates and, if necessary, adjusts the positions of the bevels at seams and slots/splitters in the following situations. Bevels may also be removed based on the evaluation.

-

The contour of the plate having the seams is modified by extending or shortening the plate.

-

The plate having the seams or slots/splitters with bevels is copied or moved.

-

The relations of the plate having the seams or slots/splitters with bevels are modified.

-

The seams or slot/splitters with bevels are modified, copied, moved or removed.

-

The holes related to the seams with bevels are modified, copied, moved or removed.

Note that some of the bevels could be removed if the Bevel Repair Tool tool is run with the Delete bevels that cannot be repaired option after plate or seam modifications.

If a seam with a bevel is removed from a panel, and the removal is undone with the Undo or Undo Removal function, the bevels at the removed seam will be restored with the seam. However, other bevels which were removed with the seam removal will not be restored. See the example below. To get these bevels back, you must run Bevel Generator. Note that Bevel Generator only restores automatically placed bevels; it does not restore manually placed bevels.

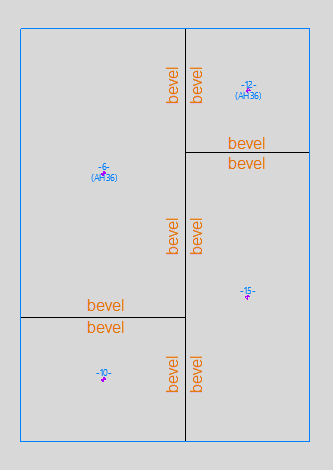

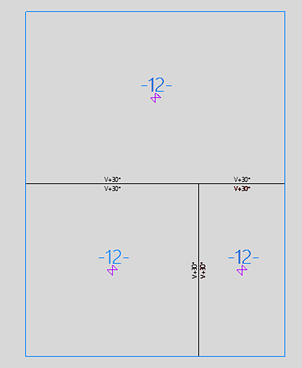

The first image shows a panel with 3 plate parts. When the vertical seam between the two lower plate parts is removed, the two plate parts are combined into one. The system removes two bevels from the horizontal seam, and repositons the remaining two bevels at that seam. The result is shown in the second image.

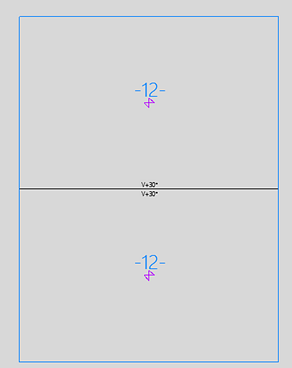

If the user performs an undo removal action, the system restores the removed vertical seam and the two bevels at this seam. The bevels that the system removed from the horizontal seam cannot be restored. The system also removes the lower bevel at the horizontal seam because a bevel can only belong to one plate part. The result is shown in the third image.

If the Bevel Repair tool is run with the Delete bevels that cannot be repaired option in this situation, the upper bevel left on the horizontal seam will also be removed.

Running Bevel Generator will get all the bevels back and restore the situation shown in the first image.

Manual bevels

Manually added bevels are always placed on the edge of a plate part, not on the entire edge of the panel. Bevels can also be placed at holes and slots/splitters on the panel. The system automatically updates the positions of manually placed bevels when the plate relations are changed.

The system also creates a bevel at the adjacent plate part's edge when the plate part edges are facing each other and are connected with a weld.

Running Bevel Generator will not modify manually placed bevels. Bevel Generator may add a bevel at a location where a manually placed bevel was deleted.

Note on manual bevels on a split plate edge

When you split a plate (or a plate part) with a seam to create two plate parts, the system will automatically reposition the existing bevels on the split edge so that they are placed on one of the plate edges.

You can manually add bevels to the other plate edge, on the edge that was split. If you remove the seam later on, the plate parts will be recombined. At this point the system will automatically remove the bevels that you manually added, and will readjust the positions of the initial two bevels.

Extra Length bevel property

Extra length is a bevel property. Extra length for predefined bevels is set in System Management > Construction > Welds/Bevels > Predefined Bevels, in the Extra length tab. The extra length property can also be set while inserting or modifying a single bevel.

-

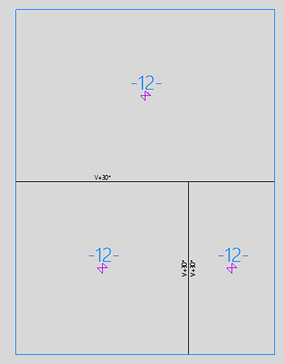

Extra length for plates can also be added and modifed with the Construction > Plates > Insert or Modify > Extra Length function.

-

Extra length for seams can be added and modified with the Construction > Welds > Insert or Modify > Extra Length function.

Inserting extra length creates a type I bevel with extra length property. Modifying the extra length modifies the extra length property. The extra length property of any bevel type can be modified.

Note: The weld opening of the bevel and the extra length have a cumulative effect on the plate edge. Weld opening is also a bevel property. It can be set in the Weld tab.