Doubler Plate

On the Structural tab, the Doubler Plate tool allows you to insert plates at the ends of beams and straight pipes. The insertion tool can align the plate with either the end of the target object or the face of a nearby object, such as a wall or floor. The end of the beam or pipe can be automatically shortened to accommodate the plate. If the target part belongs to a Structural Unit group, the doubler plate is also added to that group.

In the 3D model, a doubler plate added to a pipe is modeled as standard part that does not belong to the pipeline, and therefore, is not bound to the piping specification.

The collision detection does not report contacts or collisions between a doubler plate and the associated objects, as long as the doubler plate remains unmoved, preserving its associations with the other parts.

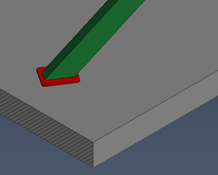

In the picture below, a doubler plate has been inserted between a beam and the floor, with the end of the beam auto-trimmed to align with the floor's surface.

Inserting doubler plates

You can insert a doubler plate at the end of a beam or straight pipe.

Prerequisites

-

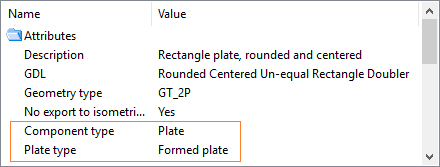

The catalog part for the doubler plate must have the attributes Component type = Plate and Plate type = Formed plate, and the related GDL object should define one parametric plate primitive. The insertion tool extracts boundary and thickness information from the plate primitive to determine the smallest plate size that can cover the end of the target object.

Note: We recommend that you use existing samples from the CADMATIC example project to create your own doubler plate parts.

-

To shorten/trim the target object, the object must be checked out to you.

Do the following:

-

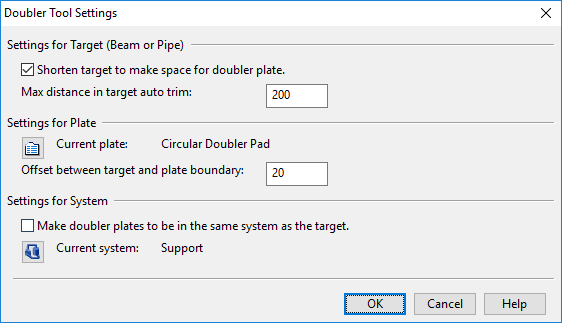

Select the Structural tab > Doubler Plate group > Add. The Doubler Tool Settings dialog opens.

-

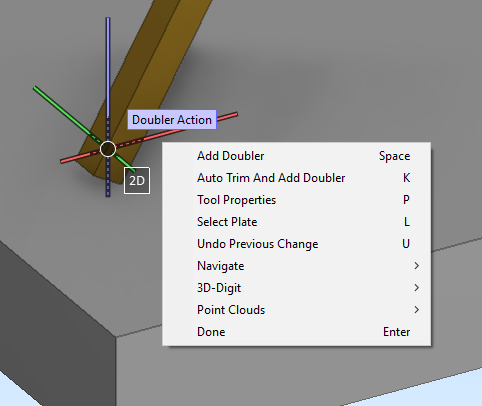

Specify the required settings, and click OK. The cursor's tooltip displays "Doubler Action" and the context menu contains commands specific to this tool.

-

You can now insert doubler plates to beams and pipes in the following ways:

-

To insert a doubler plate at the end of a beam or pipe, position the cursor over the end of the target part, click or select Add doubler (Space), and then press Enter. The plate is aligned with the target part, and the plate shortens the target part if you specified so in the settings.

-

To insert a doubler plate between a beam or pipe and a structural object, position the cursor over the end of the target part, select Auto trim and add doubler (K), and then press Enter. If a suitable "trimmer object" is found near the part's end, the tool aligns the plate with the trimmer object and auto-trims the beam or pipe with a planar face obtained from the trimmer object.

-

-

After inserting at least one plate, you can do the following:

-

You can change the settings for the next insertion by selecting Tool properties (P).

-

You can change the plate part for the next insertion by selecting Select plate (L).

-

You can undo insertions, one plate at a time, by selecting Undo (U). There is no 'Redo' command within the tool.

-

-

To stop inserting doubler plates, press Esc to exit the tool. After this, you can undo/redo the insertions, one plate at a time, by clicking Undo/Redo in the quick access toolbar.

Doubler Tool Settings

In the Doubler Tool Settings dialog, you can specify the following settings.

Settings for Target (Beam or Pipe)

-

Shorten target to make space for doubler plate – If selected (default), the beam or pipe will be shortened by the thickness of the doubler plate. Shortening is possible only if the target objects are checked out to your area model.

-

Max distance in target auto trim – Specifies the maximum search distance from the beam or pipe to a potential auto-trimmer object.

Settings for Plate

-

Current plate – Specifies the catalog part to use for the doubler plate. Click the

button to select the part from the object browser. When inserting a plate, the tool selects the smallest applicable plate size from this catalog part.

button to select the part from the object browser. When inserting a plate, the tool selects the smallest applicable plate size from this catalog part.Note: In this context, the Object browser only lists catalog parts that are formed plates. Folders that do not contain any are displayed as empty.

-

Offset between target and plate boundary – This setting guides the insertion tool in selecting a plate size that is larger than the cross-section of the beam or pipe, measured at the point where the target object is trimmed. Increase the offset value to force a larger plate size to be selected. For example, if the offset is 30 mm and the target object's cross-section is 50 mm, the tool searches for a plate size with a cross-section of at least 80 mm.

Settings for System

-

Make doubler plates to be in the same system as the target – If selected (default), the doubler plate automatically belongs to the same system as the target object. To use a specific system, clear this option and then click the

button to select the required system.

button to select the required system.