Extra Length/Shrinkage

Production > Plate Cutting Data > Extra Length/Shrinkage

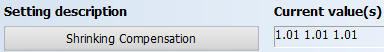

Shrinking Compensation

Set the default shrinkage compensation for all parts in the entire block.

The default shrinkage compensation increases or decreases all inner construction parts in the three directions (length, width, height) by applying a scaling factor. This setting has an effect on both the outer contour and all the holes of the part. Since this setting applies to all parts to be coded (including slanted parts and parts with knuckles) it should be used with caution.

This setting can be disabled by typing in uit as the value. This is the default value, meaning that the overall default block-level shrinkage compensation is disabled. To enable the default shrinkage compensation, enter the desired shrinkage compensation values in length, width, and height.

Note that this setting does not override the shrinkage compensation set for any individual part.

Note: The Shrinking Compensation setting in System Management works only when using a number that is a decimal of 1.

Note: If the Include Shrinkage Compensation setting is enabled, 3D models may get stretched and displaced in Hull Viewer.

See also Shrinkage management levels in the Generating Production Information User's Guide, and Shrinkage compensation in the Managing Production Information Administrator's Guide.

For information specific to shrinkage management for shell plates, see Shrinkage compensation for shell plates in the Shell Plates Reference Guide.

Margin/Trimming Prefix (Pos.)

Set a prefix to indicate that a part has a positive margin or trimming. The prefix and the amount of extra length or trimming will be placed on the part where the modification is situated. This setting can be disabled by typing in uit as the value (this is the default value).

Margin/Trimming Prefix (Neg.)

Set prefix to indicate that a part has a negative margin or trimming. The prefix and the amount of extra length or trimming will be placed on the part where the modification is situated. This setting can be disabled by typing in uit as the value (this is the default value).

Weld Codes

Define the available weld codes. You can specify the maximum plate thickness, lead of the weld, and shrinkage for each code.

Plate Shrink.Comp. For Profile

With this setting you can define how profiles are compensated in manual shrinkage compensation.

-

When set to Disabled (default), the system uses the values set in %ncgnorms%\shrinkage\settings.dat for compensating profiles. This file defines shrinkage compensation factors for different profile types in different plate thickness ranges. Additionally, the material types of the profiles can be considered as well. See Settings file for profile shrinkage compensation.

-

When set to Enabled, profiles get the same amount of shrinkage compensation that is manually added to the plate they are connected to, if the Compensate profiles in length option is selected when adding the shrinkage compensation. If the option is not selected, profiles are not compensated manually. Manual shrinkage compensation is added in Construction > Welds > Compensation > Shrinkage.

See Shrinkage management for profiles in the Generating Production Information User's Guide for more information about shrinkage compensation for profiles.

Include extra length snipe/radius

This setting is a threshold value for the size of a snipe or rounding radius on a plate contour.

When the snipe or rounding radius is larger than the set value, the extra length placed on a plate edge affects the snipe or rounding radius size. The snipe or rounding radius is enlarged in the case of positive extra length, and decreased in the case of negative extra length.

Snipes and rounding radii smaller than the set value are not affected by the plate's extra length.

Bevel Handling

Set how bevel information is handled in the plate coding process when a plate edge has both extra length and a bevel.

Only markings, no codes (default) – Consider bevel information, but only include bevel markings in the DXF, not bevel codes.

Both markings and codes – Consider bevel information, and include both bevel markings and bevel codes in the DXF.

Ignore bevel – Ignore bevel information. Do not include bevel markings or bevel codes in the DXF.