W line (lug Line)

The lug line in a cutout type file is used when a lug is added to a cutout of that cutout type. This is logistical information. See Lugs to small part or Lugs to small profile for information on how to generate the production information.

The cutout type file controls the plate thickness and material type of the lug(s). This is to avoid different material and thickness of the lugs in case two or more lugs are used for one cutout. See Thickness and material type below.

Also the dash number controls the cutout. See Dash number below.

Type files for cutouts and lugs can be extended to include bevel information. See Defining weld lines for cutouts and lugs.

Lug line

The lug line starts with character W, which is followed by several values. The following values must always be included after the character W, in the order presented here:

W <Thickness> <Material type> <Dash number>

The W line in the lug type file should contain the following logistical/production information:

W <Profile type> <Weld length> <Description>

Note: The weld length was is legacy information and can be set to zero. Weld information should be defined using bevel information variables. See W line in Defining weld lines for cutouts and lugs.

Note: The number of characters in the W line must not exceed 160.

The R1, H1, B1, and V1 operators can be used with each value.

The description concludes the lug data and need not be in quotation marks.

The following examples indicate how the W Line can be used:

Cutout type file:

W 10 ST42 1

W R5 ST42 0

Lug type file:

W PL 100 Lug type 113

W ST 100 Lug type 112

For information on how to define the part number of the lug, see refer to the Part number for lugs

Using conditional statements with the W line

It is possible to use IF and ELSE statements in the W Line in the type files of cutouts and lugs.

-

It is not mandatory to have IF statements in a W line.

-

A type file can contain multiple W lines each having IF statements, with or without ELSE statements.

-

If the W-line contains an IF statement, the IF part is closed by a colon (:).

See IF, ELSE and LET statements for more information on the syntax of these statements.

Below is an example where two conditional statements are evaluated. The last line defines the default, which is applied if neither of the IF statements are true:

IF TB>V8 : W -1 ALM 1

IF TB>V9 : W -1 AH10 1

W -1 ST42 1

The last W line defining the default is optional. You can create type files with or without this default W line. If none of the IF statements is valid and there is no W line defining the default, no weld information is applied.

ELSE conditional statements can also be used after IF statements. These will apply if none of the conditions above it are met:

IF TB < V8 : W -1 ALM 1

ELSE W -1 ST42 1

Thickness and material type

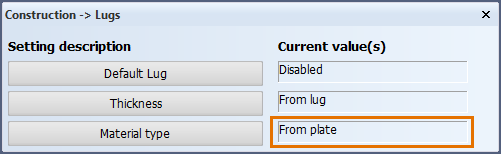

The thickness and/or the material type of the plate where the lug is placed can be used instead of the thickness/material of the lug (as defined in the logistical record). This can be done by changing the Thickness and/or Material type settings in System Management > Construction > Lugs.

-

If the value of Thickness is <=1 in the W Line of the type file, the plate thickness will be used even if the Thickness setting is not set to From plate. The thickness direction is standard in the opposite direction of the plate. A negative thickness will change this direction.

-

If the Type of material is not defined in the type file, plate material will be used even if the Material type setting is not set to From lug.

Dash number

The dash number is used to dash the lug or cutout depending of the thickness direction of the lug.

-

If Dash number is zero, no dash will be applied to the lug and cutout. It will be draw as normal lines.

-

If Dash number is negative, only the lug will be dashed. In this case the used dash pattern is the value of Dash number as positive number. In all cases this depends on the thickness direction of the lug in respect of the plate position.

-

If the Dash number is positive, the total cutout or lug will be dashed, depending on the thickness direction of the lug and plate.

Weld information

Weld information can be included in cutout and lug type files using bevel information variables. See Defining weld lines for cutouts and lugs.