Plate relations to profiles

The following describes how the system determines the connection type when it applies automatic plate beveling to plate-to-profile relations. The connection type is either connection to a part in plan view or connection to a part in cross-section.

The plate can have an angle to the profile. In this case the system adjusts the plate size to prevent gaps and overlaps in the connection. See Automatic plate size adjustment.

The bevel that is applied in each case is defined in plate beveling rules. See Plate beveling rules.

Connection to part in plan view

The relation between a plate and a profile is considered to be a connection to a part in plan view in the following cases:

-

The relation is to a profile in plan view, and the plate plane is in line with the profile body.

-

The relation is to a bulb bar profile, and the plate plane is in line with the molded side of the profile.

-

The relation is to a flat bar, H-bar, half round, or a user defined profile.

Angled connections: The angle between the plate plane and the profile body must not exceed 45 degrees or it will not be considered a connection to a part in plan view. If the angle exceeds 45 degrees, the connection is considered to be connection to a part in cross-section.

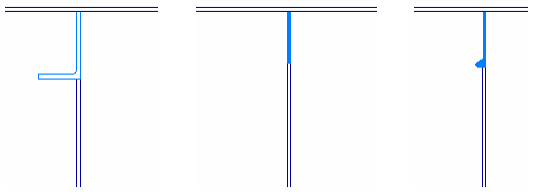

Plates related to profiles in plan view (presentation in cross-section)

Left: Connection to bulb bar at the profile molded side, with an angle less than 45°

Middle: Connection to bulb bar, plate plane in line with the profile molded side

Right: Connection to H-bar

Connection to part in cross-section

The relation between a plate and a profile is considered to be a connection to a part in cross-section in the following cases:

-

The plate is related to a profile at the profile flange.

In this case the flange thickness should be used in the plate beveling rules (variable th_1 or th_2)..

-

The relation is to a profile in plan view but the plate plane is not in line with the profile body.

-

The relation is to a bulb bar profile and the plate plane is not in line with the molded side of the profile.

-

The angle between plate plane and the profile body is more than 45 degrees.

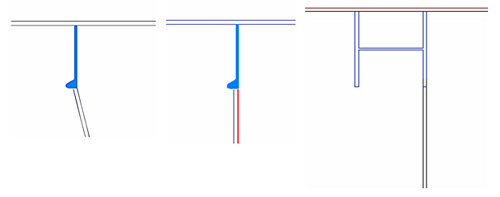

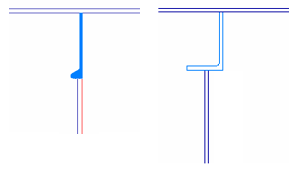

Left: Connection to bulb bar, plate plane not in line with profile

Right: Connection to profile flange