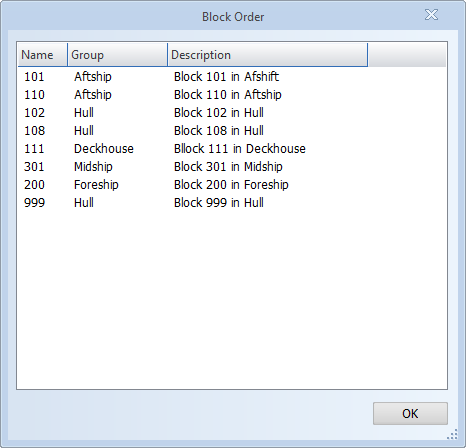

Block Order

Production > Block Order

Define the assembly order of blocks. This the order in which blocks are joined together.

Important: Only one user at a time can access this function with full access. Meanwhile, other users will not be able to open a block or a drawing in the project. Furthermore, this function cannot be opened with full access if another user has accessed the Building Block Overview, Block Groups, Quick Block Definition Tool or Reassign Blocks to Groups function.

The Block Order dialog shows all the blocks in the project, both defined and predefined. The block at the top is the first one in the assembly order. The second one is joined to the first one, the third one is joined to the second one, and so on.

Move a block up and down on the list by dragging with the mouse.

To move a group of adjacent blocks, hold down Shift, click on the first and last block in the group, and drag the group to the desired position. Hold down Ctrl to select non-adjacent blocks.

Click OK to save the block order.

See also Weld management and traceability.

The welded connection between two blocks is called a block joint weld.

Of two consecutive blocks, the one which is lower in the block order list gets the block joint weld between the two blocks, and the weld line is placed on that block.

Note: Even though the block lower in the block order gets the block joint weld, the weld is not necessarily based on the bevel attribute in that block. The weld is based on the bevel attribute of the higher block if the higher block has a more complex bevel. For example, if the bevel in the higher block has tapering, but the bevel in the lower block does not, the weld in the lower block is based on the bevel in the higher block.

The complexity of a bevel is determined by the following properties, in the given order, from more complex to less complex.

-

Tapering: tapering on both sides > tapering on one side > no tapering.

-

Bevel type: K > X+ and X- > X > Y+ and Y- > V+ and V- > I

-

Thickness difference between the connected parts. The bevel on the thicker part is considered more complex.

For example, a tapered bevel is considered more complex than not tapered. If there is no difference in tapering, the bevel type determines the complexity. The K bevel type is considered the most complex, and the I bevel type the least complex. If the bevel types are the same, the bevel on the thicker part is considered more complex.