Shell Plate Elongation Reports

Elongation reports are needed for the shell plate production personnel. They help to bend shell plates accurately.

For information on what to consider regarding elongation and the bending process, see Elongation and shell plate bending overview.

An elongation report is an Excel file that contains information about the elongation that is required to successfully produce the shell plate. It shows how much deformation is needed to give the shell plate its final shape, showing the amount of elongation in the different parts of the shell plate.

The system creates an elongation report for each shell plate when shell plates are coded.

Elongation can be presented in two alternative ways in the elongation report:

-

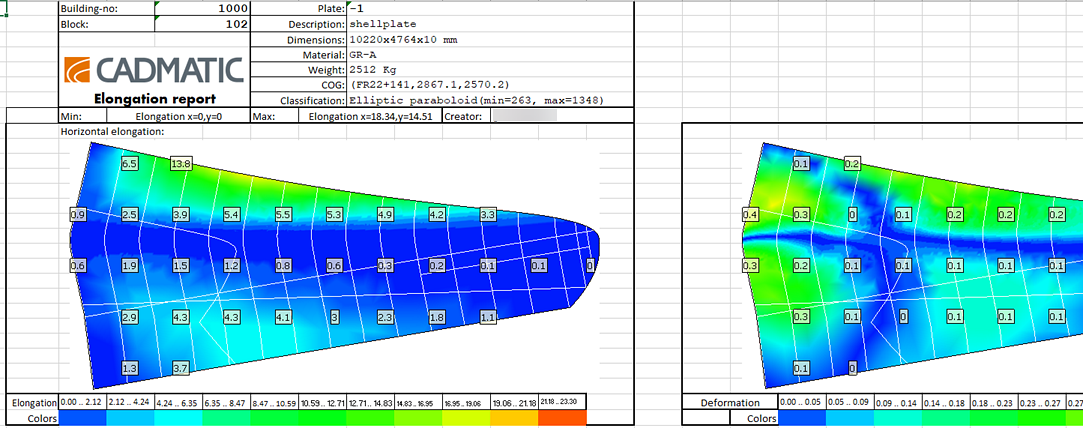

As 2D shell plate images separately for the horizontal and vertical elongation (x direction and y direction, respectively). Labels on the images show the elongation values at multiple grid points on the shell plate. The elongation values are strain values per meter (by default). A color map where the colors represent different elongation values is also projected on top of each image. Also an image showing the plate deformation in angles can be included. The angular deformation values represent the shear strain.

The flattened shell plate contour is shown in black. The inner construction and templates are both shown as white marking lines.

Show/hide image

Show/hide image

Upper part of the default elongation report. General shell plate information at the top. Below that, shell plate images with color map. The left image shows horizontal elongation values, and the right image shows deformation in angles.

-

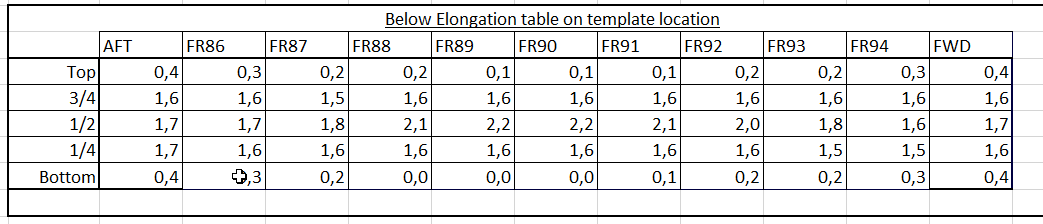

As a table showing the elongation values at multiple points where the shell plate intersects with its templates. Each elongation value is a combination of the horizontal and vertical strain, perpendicular to the template line, calculated as an average of 9 sampling points.

Show/hide image

Show/hide image

Elongation table showing elongation values at intersection points with templates. The lines represent positions in the shell plate from the top to the bottom in evenly distributed distances. The columns represent templates and they run from aft to fore. Each cell contains an elongation value at an intersection of the shell plate and a template.

Which presentation is used depends on what is included in the elongation report template, and should be decided according to the needs of the production personnel responsible for the bending of the shell plates.

The default location of the generated elongation reports is by default the block folder's pi subfolder. This location can be changed in System Management > Production > Shell Plates Elongation List > Settings > Report Output Directory, and the default report name Elongation[part] in Report File Name.

The system creates the elongation reports based on the elongation report template elongationreport.xls. The elongation report template is located in the cvar folder of the project norms. The standard norms contain an example template which can be customized the specific needs of the production.

The system administrator should define the limits for the elongation by setting the minimum and maximum values for elongation, called extremity rules. The maximum allowed elongation depends on the thickness and material type of the shell plate.

The elongation values are expressed in the elongation report using different colors on the plate. The system administrator should define the color ranges that are used for indicating the different elongations. This is done by setting the color rules for elongation reports.

See the following topics in the Shell Plates Reference Guide for more information: