Hole Status

Construction > Holes > Status

Change the type, acceptance status and lock status of a hole. Changing the status is only allowed when the block containing the part(s) affected by the selected hole(s) is checked out.

You cannot change the status of holes which are under work in Outfitting, shown as Locked by Outfitting. The Outfitting user must first request an update for the hole request. For more information on hole request states, see Hole request states.

Note: In shell plates, the status of only standard holes (fixed holes) can be changed. The status of shell holes created using closed hull lines cannot be changed; they are always considered to be accepted and will be cut (burnt).

In 3D-Contek you can change the status of standard and arbitrary holes.

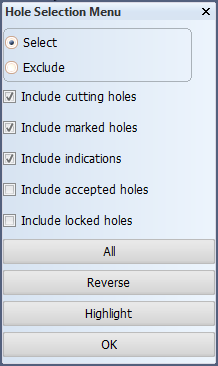

The settings in System Management > Construction > Holes > Change Hole Status define which options are selected by default in the Hole Selection Menu and Hole Status dialogs.

Do the following:

-

In the Hole Selection Menu dialog, select holes with a certain status. You can then change the type, acceptance status and lock status for holes with these statuses only.

-

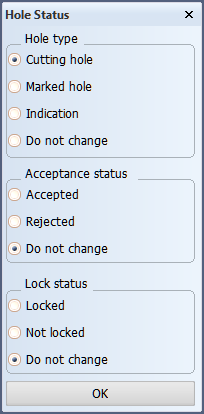

Click OK. The Hole Status dialog opens.

-

Select the desired hole type.

-

Select the desired acceptance status.

-

Accepted – The hole status is set to accepted, and the holes will be visible in production data and 3D models.

-

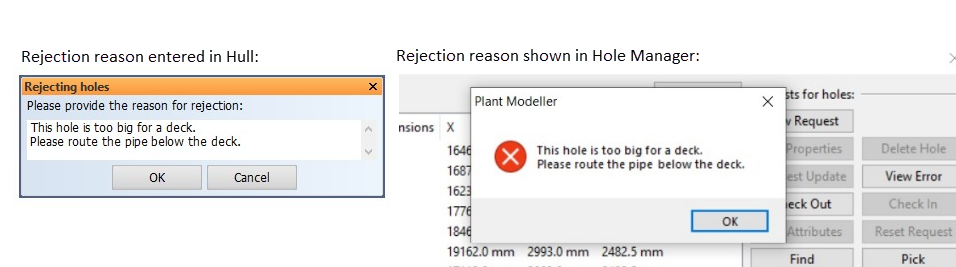

Rejected – The hole status is set to rejected, and the holes will be removed from all Hull data. You will be prompted to enter a reason for the rejection. In Plant Modeller, the reason will be shown when clicking View Error in Hole Manager.

-

Do not change – The hole status will not be changed.

-

-

Select the desired lock status for Outfitting holes:

-

Locked – The holes cannot be modified in Outfitting.

-

Not locked – The holes can be modified in Outfitting.

-

Do not change – The hole status will not be changed.

Note: This option only affects Outfitting holes; it does not affect holes created in Hull.

-

-

Click OK. The system will now process each hole request. This involves storing the new status in COS, and for each request, determining all Hull parts that contain (a part of) the hole. Each of these "affected" parts is recalculated on the Hull Server.

Note: Automatic processing of affected parts by the Hull Server is only possible for parts in the active block. When non-standard Solid/Dash settings are active (Tools > Settings > More Settings > Block Properties) or the hole affects parts in other blocks, it is possible that one or more parts cannot be automatically recalculated. When the block with the RFH 'ownership' is already checked out, simply entering the block will trigger the Hull Server. If not, you should manually check out the block and also manually recalculate the parts. While processing hole requests, the Hole Status function will inform you of the necessary steps. See also Handling of hole requests in relation to blocks.

In 3D-Contek, the Production > Production > Report > Hole List function relates to this. For more information, see Hole list in the Generating Production Information User's Guide.