Processing codes for parts

Special processing codes can be used in reports for parts: process code, job code, article number, position. These codes can be added to the logistical database with the Production > Logistics > Process Codes function.

Each code gives information about the construction for the manufacturing process, and they can be used to control production. Another use for these codes is to use them in the selection of parts and generate reports or other production data of this selection.

The codes are as follows:

-

Process code. The code can consist of either numbers of alphabetical characters.

-

Job code The code can consist of either numbers of alphabetical characters.

-

Position of the part

-

Article number

-

Description of the part

It is also possible to rearrange the assembly order:

-

Order by creation

-

Order by relation

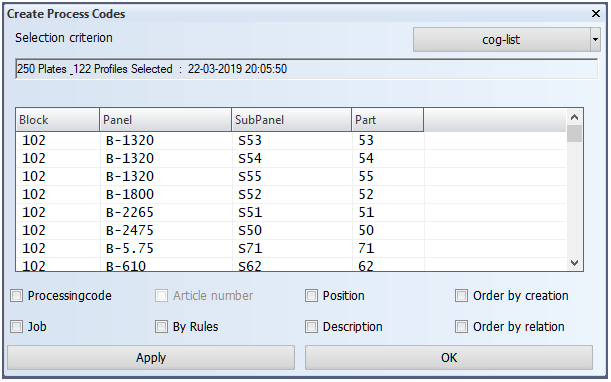

There are options to select which code should be calculated (for the first time or again). Clicking Apply or OK starts the process where all parts are given new codes. The Apply action keeps the function active so that another selection can be made.

The codes are defined in the settings under Logistics > Process and Job Codes in System Management

Creating a new part selection

The Create Process Codes dialog displays the number of plates or profiles that have been selected, and an overview of these parts. The previously made selection is the default selection, and is shown in the dialog when the Create Process Codes function is started. A new selection must be made if this selection is not up-to-date any more.

The displayed selection's date and time indicate when this selection was made. The Selection criterion drop-down menu opens the standard selection menu where you can enter the desired selection criteria. This will make a new selection. Once the new selection has been made, the system refreshes the number of the selected parts and the selection date and time.

Selection in a Hull Viewer can be used for some parts (Hull Viewer option of Selection criterion).

Note: Only the selected construction will be processed.

Process code and job code

Selecting Processingcode or Job adds the process codes and job codes to the logistical database, respectively.

How the process codes and the job codes are used can differ depending on the needs of the production. For example:

-

The process code can be used to define a certain activity, like bending. This way it is possible to control the order of the different steps in the production process of each part type.

-

The job code can be used to control the order of processing several parts which have different process codes.

The process and job codes are by default numbers. Characters can be used as well. Whether numbers or characters are used is defined with the Process/Job Code Method setting in System Management > Logistics > Process And Job Codes > Process And Job Code Numbers.

-

Number codes are defined in Process And Job Code Numbers.

-

Character codes are defined in Process Code Characters and Job Code Characters.

Important: If the character method is taken into use in a project which is using the number method, the data type of the Processingcode and Jobnumber logistical database fields must be changed from Integer to Character. This can be done in System Management > Logistics > Logistical Database Layout. If the method is later changed back to number-based, the logistical database fields must be set back to Integer.

By rules

With this option it is possible to modify the logistical information of the selected parts so that the values of logistical fields get their values according to rules. The affected logistical fields, and the rules by which their values should be determined, are defined in System Management > Production > Logistics > Use Rules.

This option is only available if at least one setting has been defined in the Use Rules settings.

Position

When the Position option is selected, the position of the part is stored in the logistical database in the [Position] field. Positions have the following values:

-

1 starboard

-

-1 port

-

0 centre line

Note: When a process code, a job code or a position is used, the values can be converted to names. This can be done by enabling the conversion in the Convert column in System Management > Logistics > Logistical Conversion > Convert Logistical Data. The replacement name is defined in System Management > Logistics > Logistical Conversion > Conversion Settings. For example for the positions, SB, PS, and CL can be used instead of 1,-1 and 0.

Description

When the Description option is selected, all standard descriptions that have been set with the settings in Logistics > Description in System Management will be written to the database again. This means that whenever a standard description has been changed, this change will be made throughout the database, so that the entire description will be up-to-date again.

Note: The description of parts is always made up to date after creating or modifying the parts. It is only useful to use this function after changing the defaults descriptions. For example, to switch to a different language.

Order by creation time

When the Order by creation option is selected, all selected items (preferably all items in the block) will get a new work breakdown tree order based on the creation time of the plates. The related attributes of the plate will follow the plate order.

Order by relations

When the Order by relation option is selected, all selected items (preferably all items in the block) will get a new work breakdown tree order based on the mutual relations of the plates. The related attributes of the plate will follow the plate order.